In the dynamic world of construction, companies are constantly seeking reliable and efficient solutions. One standout option, notably for foundation stabilization, is helical piers.

Let’s delve into the nuts and bolts of how these genius contraptions can transform the way construction companies approach foundation stabilization and repair.

What is foundation stabilization in construction?

Foundation stabilization refers to the process of strengthening and stabilizing the foundation of a structure to prevent or correct issues related to ground movement, soil settlement, or other factors that might undermine the foundation's integrity.

The main objective of foundation stabilization is to ensure the longevity and safety of a structure.

Here are some reasons why foundation stabilization might be needed:

- Soil Settlement: Over time, the soil beneath a foundation can settle at uneven rates, causing cracks and other structural issues.

- Expansive Clay Soils: Certain soils, like expansive clays, swell when wet and shrink when dry. This can lead to significant movement beneath a foundation.

- Soil Erosion: Erosion can wash away soil from under a foundation, leading to voids that can cause the foundation to settle or crack.

- Improper Soil Compaction: Before a foundation is poured, the soil is typically compacted. If this isn't done properly, the soil can later compress under the weight of the structure, leading to foundation issues.

- Ground Movement: This includes land subsidence or ground heave.

- Influence of External Factors: This might include nearby construction activities, vibrations, waterlogging due to poor drainage, or tree roots growing beneath the foundation.

What are the primary benefits of incorporating helical piers (piles) into construction projects for foundation stabilization?

Helical piers, also known as helical piles or screw piles, are a type of deep foundation system that can be used for a variety of construction and structural support purposes.

They have several advantages over traditional foundation methods, particularly in challenging soil conditions or sites.

Here are the primary benefits of incorporating helical piers/piles into construction projects for foundation stabilization:

- Speed of Installation: Helical piers can be installed quickly, often in a fraction of the time it takes to install other types of foundation systems. This can result in reduced project timelines and associated labor costs.

- Minimal Equipment: The equipment required to install helical piers is typically smaller and more portable than the machinery needed for driven piles, drilled shafts, or other deep foundation systems. This is particularly useful in sites with limited access.

- Versatility: Helical piers can be installed in a variety of soil types and conditions, including areas with high water tables, marshy grounds, or areas with fill soils.

- Minimal Site Disturbance: Since the installation process involves screwing the pile into the ground, there's limited excavation required. This results in minimal soil disturbance, reducing the need for site cleanup and potential landscape impacts.

- Immediate Load Bearing: Helical piers can often bear loads immediately after installation. This contrasts with some other foundation systems that require time for concrete to cure or soils to consolidate.

- Adjustability: If a helical pier doesn’t achieve the desired bearing capacity at the anticipated depth, additional helix-bearing plates can be added, or the pier can be extended to a deeper soil layer.

- Cost-Effective: In many scenarios, especially where traditional foundation systems would require significant site preparation or extensive excavation, helical piers can be a cost-effective solution.

- Predictable Performance: The torque applied to install a helical pier can be continuously monitored, providing real-time data that's correlated with the pile's load-bearing capacity. This allows for more predictable performance and assurance that the pile is installed correctly.

- Use in Remedial Applications: Helical piers are not just for new construction. They can be used in remedial applications to stabilize and lift existing structures that are experiencing settlement.

- Cold Weather Installation: Unlike some construction methods that are hampered by cold weather conditions, helical piers can be installed during colder months, given that the ground isn't frozen solid.

The Science of Soil and the Brilliance of Helical Piers/Piles in Keeping Foundation Stability

Different soils have unique characteristics, and as a builder, understanding these properties is vital. From silty clay to sandy loam, helical (screw) piles are compatible with a wide spectrum of soil conditions. Here’s how:

- Sandy Soils: While sandy soils can be prone to shifting, helical piers anchor deeply and securely, mitigating the effects of soil movement.

- Clayey Soils: For soils with high clay content, which are prone to expansion and contraction, helical piers offer a stable solution that resists these changes.

- Rocky or Mixed Soils: In regions with rocky or mixed soils, helical piers can be designed to penetrate through the challenging layers, offering rock-solid stability.

Mastering the Art: Ensuring Flawless Helical Pier Integration in Construction Design For A Stable Foundation

Ensuring proper engineering and design when using helical piers in foundation stabilization is essential for the safety, longevity, and functionality of the structure. Here are some of the steps construction companies typically take:

Soil Investigation: Prior to commencing any excavation, a thorough assessment of the soil's properties is essential to understand its characteristics and composition.

Engage Qualified Engineers: It's paramount to involve engineers with proven expertise in helical pier systems, professionals who possess a deep understanding of soil mechanics and foundation dynamics.

Load Analysis: Accurately assess the building's weight-bearing capacity. Just as elevators have maximum load capacities, so do building structures.

Select the Appropriate Helical Pier: Each helical pier is designed with specific features tailored to particular soil conditions. It's vital to choose the one best suited for the identified soil type.

Preliminary Testing: Prior to full-scale installation, conduct preliminary tests on the helical piers to ensure their compatibility with the ground conditions.

Installation Torque Monitoring: Monitor the torque consistently during installation. It serves as an indicator of the helical pier's interaction with the soil and its stability.

Quality Assurance and Control: Maintain strict oversight during the installation process. Ensure every pier is correctly positioned and meets the required standards.

Adherence to Codes and Standards: ICC and ASTM standards are integral to this domain. Adhering to these recognized guidelines guarantees both safety and quality.

Collaboration and Communication: Ensure open and regular communication amongst all team members. Shared insights and timely feedback can greatly enhance project outcomes.

Post-Installation Verification: After installation, it's crucial to inspect and validate the work to ensure that all standards have been met and the foundation is secure.

Continuous Training: The field of helical pier systems is ever-evolving. Continuous professional development ensures that the team stays updated with the latest methodologies and practices.

Application Spotlight: Where Helical Piers Shine For Foundation Stabilization

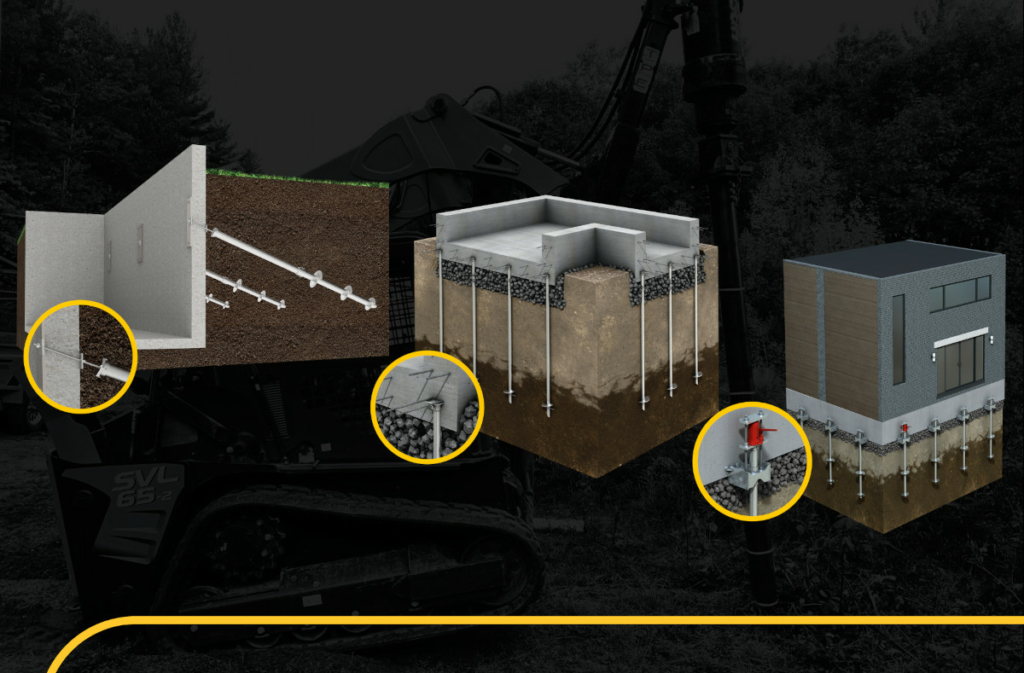

Retaining Walls

Helical piles provide an excellent solution for stabilizing retaining walls. By anchoring walls securely into the ground, they prevent collapse and soil erosion, making a property both safe and visually appealing.

Home Foundations

From new builds to existing structures, helical (screw) piles are revolutionizing home foundation solutions. They are installed without the need for extensive excavation, offering a cleaner and more efficient alternative.

Underpinning

Underpinning involves strengthening the foundation of an existing structure, and this is where helical piles truly excel. With minimal disturbance to the surrounding area, they ensure a secure and lasting foundation.

In the ever-evolving dance of construction, helical piles have taken center stage as a veritable game-changer for foundation stabilization.

Their versatility dances seamlessly with diverse soil types, and their efficient installation keeps construction timelines on their toes.

So, as the curtain falls on our helical journey, remember: whether it's sandy soils or complex loads, there's a helical pier ready to take the lead.

To all construction maestros out there – keep twirling, stay updated, and let's build a future that's grounded in excellence!

About GoliathTech

Since 2004, GoliathTech has been the most important manufacturer and installer in the helical (screw) pile industry worldwide. Our patented helical pile foundation system surpasses industry standards and has earned us multiple awards and prizes.

Carried out by certified installers, our quick installation process avoids excavation, which protects your landscape and allows you to begin building as soon as the piles are in the ground. Moreover, you can anchor GoliathTech’s helical pile foundations into any soil or space year-round. Installed deep into the ground, beneath the frost line, they solidly support the structure in even the most extreme conditions. Our technology guarantees that a helical (screw) pile foundation won't move or crack over time.

Integrating both strength and know-how, GoliathTech offers the best anchoring solution to support your residential, industrial, commercial, and municipal projects. Trust the experience and expertise of GoliathTech for your foundation projects. Find a certified GoliathTech installer in your region or become a franchisee.

Share this Article